How Industrial Lifting Became the Silent Hero of Scalable Businesses

How Industrial Lifting Became the Silent Hero of Scalable Businesses

In an age where digital tools dominate headlines, there’s a quiet but powerful transformation happening in factories and warehouses. It’s not about AI or big data—it's about how we move heavy things. Yes, lifting systems.

Lifting equipment has gone from being a basic utility to a strategic enabler of productivity. Companies that once relied on manual hoists and outdated cranes are now investing in intelligent lifting solutions—and reaping massive returns.

The Overlooked Cost of Inefficiency

Traditional lifting methods often result in delays, injuries, and maintenance headaches. This leads to increased downtime, higher operational costs, and demotivated staff. What many companies don’t realize is that these “invisible” losses can accumulate into significant business setbacks over time.

A New Era of Lifting

Smart lifting systems are reshaping how businesses operate. Electric hoists, under-slung cranes, and automated trolleys now offer features like:

-

Precision speed control

-

Wireless remote operation

-

Load monitoring sensors

-

Predictive maintenance alerts

These aren't just upgrades—they're tools that make operations faster, safer, and more scalable.

From Manual to Modern: A Real Example

A mid-size logistics firm in Gujarat upgraded its manual lifting setup to a modular EOT crane system with automated stops and overload safety. Within 3 months, their loading time was reduced by 35%, and breakdowns dropped to almost zero. No extra staff. Just smarter equipment.

Lifting = Culture Shift

When lifting systems are modernized, the benefits go beyond physical performance. Operators feel safer and more confident. Floor supervisors get more control. Overall morale improves, and this impacts retention and team ownership.

It’s about building a culture where safety and efficiency go hand in hand.

The Competitive Advantage

Companies that optimize their lifting are better positioned to scale. Why?

-

Reduced downtime = better delivery timelines

-

Higher precision = less product damage

-

Smarter maintenance = lower repair costs

-

Safer systems = fewer insurance claims

These factors influence not just operational KPIs but also how clients perceive your professionalism.

The Loadmate Advantage

India’s industrial backbone is strong, and one player making a real difference is Loadmate. They specialize in advanced lifting solutions tailored for Indian conditions—be it heavy manufacturing, warehousing, or infrastructure.

From electric chain hoists to double girder EOT cranes, Loadmate’s products are known for durability, ease of use, and industry-grade safety.

Future-Proofing with Lifting Tech

We’re entering an era where lifting systems will connect with cloud-based monitoring and AI diagnostics. Businesses that invest now will have fewer hurdles as these innovations become standard.

Conclusion

The smartest factories aren’t just automating tasks—they’re elevating how they move, lift, and handle materials. The lifting process may seem like a background function, but in the world of scalable business, it's one of the most powerful levers of growth.

If your lifting system is outdated, your growth might be too. It’s time to lift your expectations—and your results.

Asia-Pacific Functional Flour Market Driving Innovation in Food Processing and Nutrition

- Functional flour is processed or specialty flour offering five times higher water-binding capacity than conventional flour

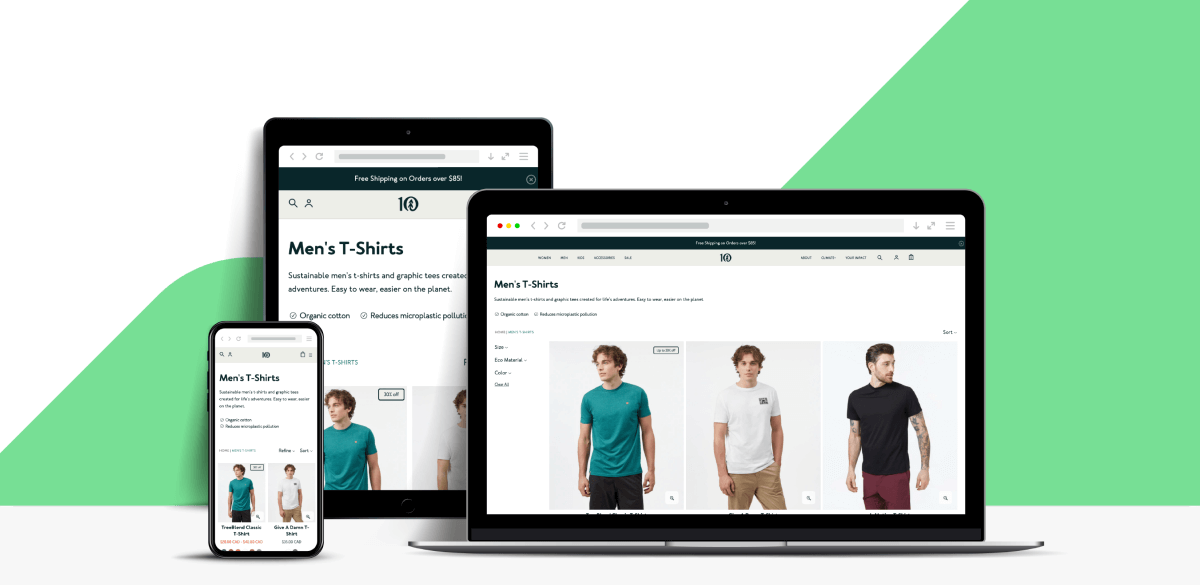

How AI Is Revolutionizing Shopify Smarter Stores Better Conversions

- Discover how AI is transforming Shopify with tools for automation personalization and smarter analytics to help your eCommerce store grow efficiently

Travel in Style and Comfort with Your Trusted Bus Rental Partner in Doha

- Travel in elegance and comfort with our premier bus rental service in Doha Trust us for a smooth and enjoyable journey every time

GullyBET Registration for Real Money Play Beginners Tutorial

- Start real money gaming today Follow this beginners GullyBET Registration guide and unlock bonuses fast play and secure access